The chili powder processing line has continuous automatic production, fast processing speed, high output, good quality, and a low-temperature drying method maintains the original flavor of chili.

It includes chili washing machine,chili air dryer(optional),chili punch(optional),chili dryer,chili color sorter,chili tail remover,chili grinder,chili powder packaging machine and other equipment. The chili powder processing line can also be used for other spices such as garlic, ginger, onion, etc.

In addition, dry ground chili is easier to store, avoiding economic losses caused by seasonal storage and mildew deterioration. The chili processing line adopts advanced technology, high chili output, and direct sales at factory prices. This is the best choice for the chili business and the most ideal equipment for chili processing at present.

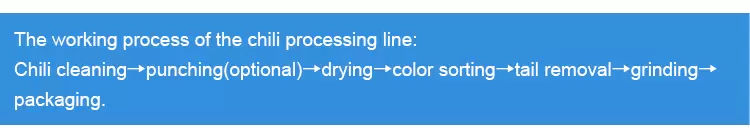

Chili processing process

The chili powder production line includes chili washing machine,chili air dryer(optional),chili punch(optional),chili dryer,chili color sorter,chili tail remover,chili grinder,chili powder packaging machine.This line is fully automatic. After processing, we can obtain chili powder and pack and store this chili powder to facilitate subsequent transportation and storage.

Chili washing machine: Clean the chili of dust and impurities, and remove debris. The whole is made of stainless steel. The chili is cleaned by the action of water circulation. After cleaning, the chili will go to the next process along with the conveyor system.

Air dryer (Dehydrator): It can effectively remove the surface moisture of chili and shorten the drying time of chili.

Chili Punch: Chili drying has its own particularity. During the drying process of chili, in the early stage of drying, the skin of the chili quickly loses moisture, and the epidermis of the chili becomes hard, which will cause the internal moisture to lose very slowly. If the peppers are punched before drying, the moisture inside the peppers will quickly lose, shortening the drying time of the peppers. Chili punching has no effect on the drying quality of chili and is suitable for large chili peppers.

Multi-layer belt chili dryer: The dryer is the key equipment, which determines the effect and quality of chili after processing. Using our mesh belt type chili dryer, with an intelligent control system, can make chili the drying is always maintained in a reasonable drying environment to ensure the effect of the finished product. The use of this chili dryer has the advantages of large processing output, high degree of automation, controllable drying effect and quality, and adjustable drying time. Flexible heat source selection: Coal, wood chips, natural gas, diesel, propane, electricity, etc.

Chili color sorter: Sort the dried peppers, remove damaged, shriveled, mildewed peppers, or remove stalks, leaves, stones and other sundries in the peppers. The machine can accurately sort out high-quality peppers according to the color difference of peppers, with fast sorting speed and high efficiency. The selected peppers are of high quality, and the net selection rate can reach more than 99%.

Chili tail remover: The main function of the chili tail removal machine is to remove the tail of the chili, and the value of the processed chili is doubled. The equipment has a fast processing speed, low chili loss, and is suitable for different varieties of chili.

Chili powder making machine: Grind dried chili to a fineness of 10-120 mesh. The chili grinder is air-cooled or water-cooled and can work continuously for a long time.

Chili powder packaging machine: Generally speaking, the chili powder business requires automatic chili powder packaging equipment. The chili powder packaging machine has a PLC control system, which is intelligent and controllable and can be quickly adjusted according to customer packaging requirements. Packaging weight and quantity are automatically adjusted.