Microwaves are electromagnetic waves at a frequency of 300 MHz to 300 GHz. The material in the heating medium in the molecules of water is a polar molecule. It is the rapidly changing under high-frequency magnetic field, its polarity orientation will be with the change of external electric field changes, resulting in molecular motion and friction between the effect, this field of the microwave field can be transformed into thermal energy within the medium, the temperature of the material increased, heating and puffing a series of physical and chemical processes, to achieve the purpose of microwave heating and drying.

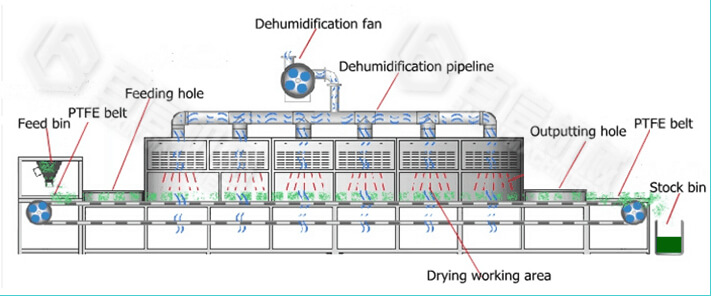

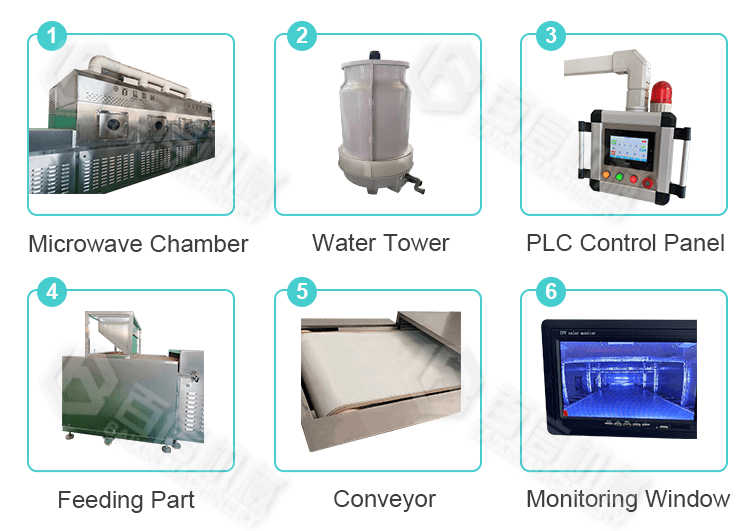

During the equipment is working the microwave generator produces the microwave. The materials enter the heating chamber by conveyor. At this time, moisture and bacteria inside the material evaporate under the action of microwave energy to achieve unfreeze sterilization ripening fixing drying purposes.

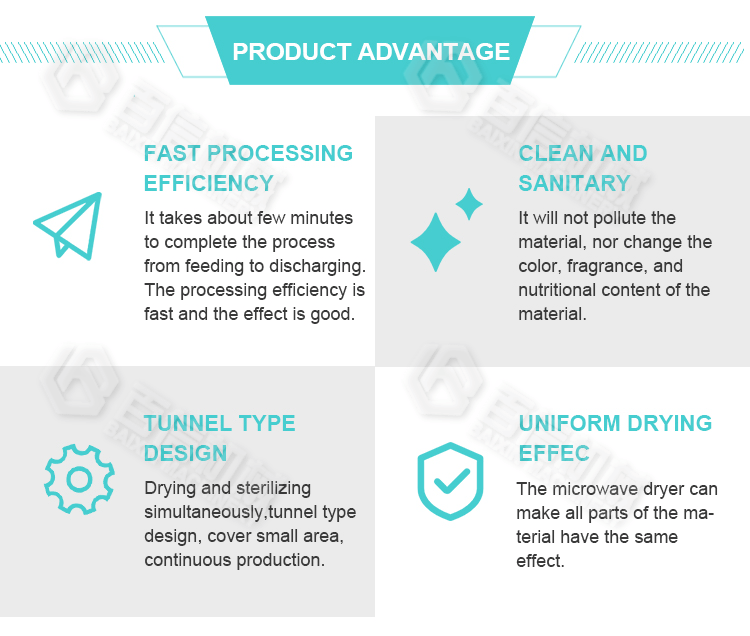

Advantages of vegetable microwave drying machine:

1:Fast processing efficiency:

It takes about a few minutes to complete the process from feeding to discharging. The processing efficiency is fast and the effect is good.

2:Uniform drying effect:

The microwave dryer can make all parts of the material have the same effect.

3:Drying and sterilizing simultaneously, tunnel type design, cover small area, continuous production.

4:Clean and sanitary: it will not pollute the material, nor change the color, fragrance, and nutritional content of the material.

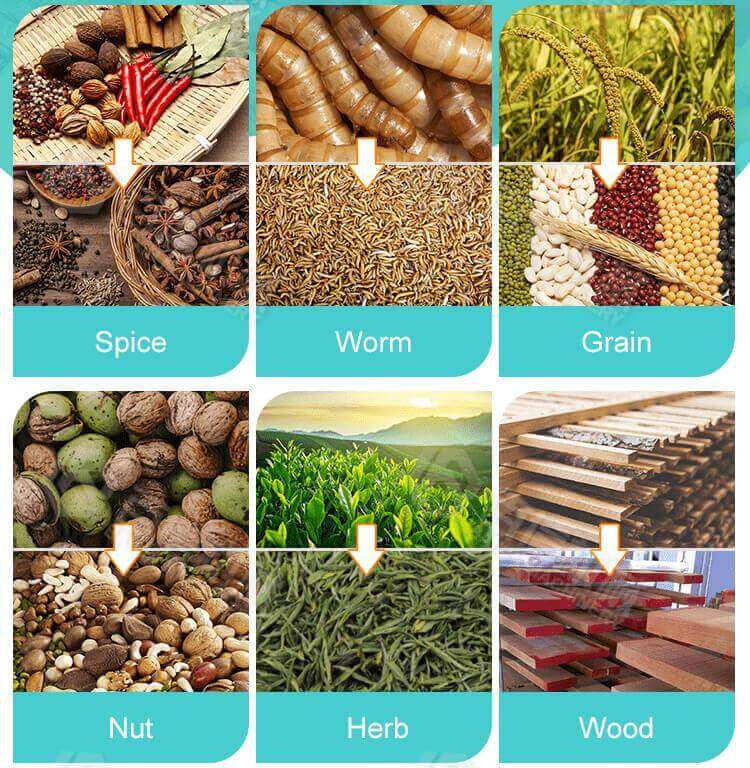

Application of vegetable microwave drying machine:

Pasta classes:non-fried fast noodles, fine dried noodles, stewed noodles.

Dehydrated Vegetables:all kinds of vegetables.

Meat :Beef ,pork ,chicken ,fish ,duck.

Grain and nuts:Filbert ,Chinese chestnut ,peanut ,nut,almond ,pine nut ,pistachio nut ,melon seeds,grain.

Worm: black soldier fly larva.

Your product is not listed above? We are ready to meet any new challenge! Contact us for free product testing!

Place the materials on the conveyor belt of the microwave dryer. The materials are dispersed on the conveyor belt through a homogenizing device on the conveyor belt. During the operation of the equipment, the microwave generator generates microwaves. The materials enter the heating chamber through the conveyor belt. At this time, the water and bacteria in the materials evaporate under the action of microwave energy to achieve the purpose of sterilization and drying. The drying time is 5-10 minutes. The dried materials are discharged from the discharge port.

| Model | Size(mm) | Power | Dewater | Cabinet | Feeding mesh width | Temperature | Control |

| BX-10 | 6300*665*1800 | 10KW | 10kg/h | 2 | 500mm | 0~400℃ | PLC |

| BX-15 | 6300*950*1800 | 15KW | 15kg/h | 2 | 750mm | 0~400℃ | PLC |

| BX-20 | 8500*1200*1800 | 20KW | 20kg/h | 4 | 500mm | 0~400℃ | PLC |

| BX-30 | 8500*1500*1800 | 30KW | 30kg/h | 4 | 750mm | 0~400℃ | PLC |

| BX-40 | 10500*1500*1800 | 40KW | 40kg/h | 6 | 750mm | 0~400℃ | PLC |

| BX-50 | 10500*2000*1800 | 50KW | 50kg/h | 6 | 1200mm | 0~400℃ | PLC |

| BX-60 | 10500*2000*1800 | 60KW | 60kg/h | 6 | 1200mm | 0~400℃ | PLC |

| BX-70 | 12500*2000*1800 | 70KW | 70kg/h | 8 | 1200mm | 0~400℃ | PLC |

| BX-80 | 12500*2000*1800 | 80KW | 80kg/h | 8 | 1200mm | 0~400℃ | PLC |

| BX-90 | 14500*2000*1800 | 90KW | 90kg/h | 10 | 1200mm | 0~400℃ | PLC |

| BX-100 | 14500*2000*1800 | 100KW | 100kg/h | 10 | 1200mm | 0~400℃ | PLC |

| BX-120 | 16500*2000*1800 | 120KW | 120kg/h | 12 | 1200mm | 0~400℃ | PLC |

| BX-150 | 20000*2000*1800 | 150KW | 150kg/h | 16 | 1200mm | 0~400℃ | PLC |

| BX-160 | 20000*2000*1800 | 160KW | 160kg/h | 16 | 1200mm | 0~400℃ | PLC |

| BX-180 | 22000*2000*1800 | 180KW | 180kg/h | 18 | 1200mm | 0~400℃ | PLC |

| BX-200 | 23400*2000*1800 | 200KW | 200kg/h | 20 | 1200mm | 0~400℃ | PLC |

| The drying machine can be equipped according to the user's requirement and the production demands. | |||||||