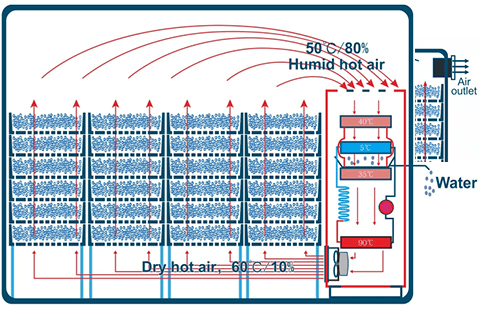

Drying essence is taking moisture away, but taking away the moisture temperature is not the most critical factor. The key for drying is depending on relative humidity within certain space, Baixin company took advantage of the dry essence, originality developed a "Closed Cycle" dryer, changed the traditional heat pump dryer "bake" to "dehumidifier”. Its several advantages were unmatched by the traditional heat pump dryer.

Baixin seaweed dehydrator has a compact structure, great energy-saving, wide application, high drying quality, easy operation, simple installation, and removable. it is the best drying equipment for small firms, drying experiments, and scientific research. The users only connect the power to use, which is the easiest operation heat pump dryer.

Advantages of the seaweed dehydrator:

Application of the seaweed dehydrator:

What can they dry?

Fruits and Vegetables, Pasta, Tea, Flowers and Leaves, Nuts and Seeds, Herbs and Spices, Meat and Petfood, Seafood.

It can be used for drying fresh food separately or even together without the worry of mixed fragrances.

Your product is not listed above? We are ready to meet any new challenge! Contact us for free product testing!

1: Pick seaweed

Due to the different quality and maturity of seaweed, unsuitable seaweed should be picked out before drying.

2: Clean the seaweed

To clean the surface dust of seaweed, if the output is large, it is recommended to use a professional seaweed cleaning machine.

3: Put the seaweed on the tray

Spread the seaweed evenly on the tray with a thickness of about 5 cm, and then put them in the drying oven.

4: Seaweed dehydration

Set the temperature in the drying room to 65°C and the humidity to 10%. Dry for 6~8 hours to complete the seaweed dehydration.

5: Storage

The dried seaweed will regain moisture when they are in direct contact with the air, so a sealed package is required. If you use vacuum packaging, you can better preserve the color and aroma of seaweed.

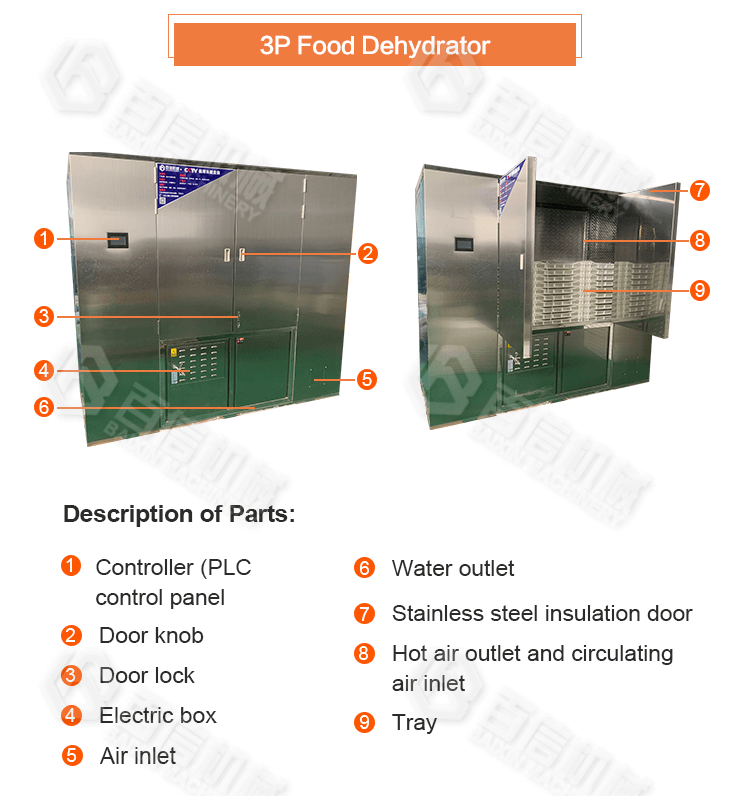

| All-in-one Food Dehydrator List | |||||||

| type | machine size(MM) | Capacity (KG) | total power(kw) | Qty of cart | Qty of tray | cart size(MM) | tray size(MM) |

| 1P | 1180×680×1800 | 50kg-80kg | 1 | — | 15 | — | 600×800 |

| 3P | 2100×930×2100 | 120kg-300kg | 3.5 | — | 40/60 | — | 600×800 |

| 8P | 4000×1960×2050 | 650kg-1000kg | 8 | 8 | 232 | 600×800 | 600×800 |