10KW Potato Microwave Drying Machine Delivery To South Korea

Our Korean customers have been processing fruits and vegetables for many years. We learned through the internet that we are engaged in the manufacture of drying equipment and consulted with us about potato drying.

The customer's output requirements are not high, and the early stage is only a project test. The customer requires that the color of the material remains unchanged during the drying process, and the drying speed is fast and adjustable.

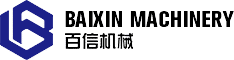

According to the customer's request, we recommended him a microwave dryer and a heat pump drying room. The final customer chooses 10KW microwave dryer. The output of this dryer is 20kg/h, and the drying temperature can be adjusted between 0 and 400°C. Continuous production is possible with short drying times and no installation required.

| 10KW Microwave Drying Machine | |

| Nation | South Korea |

| Drying material | Potato |

| Capacity | 10kg/h |

| Dehydration ratio | 75% |

| Drying temperature | 0-400℃ |

| Drying time | 5-10min |

| heat source | electricity |

| Voltage | 380V |

| Power | 10kw |

| Warranty period | 1 Year |

| Core advantages | Fast heating speed and uniform/ energy saving/ sterilizing |

Working principle of microwave drying machine

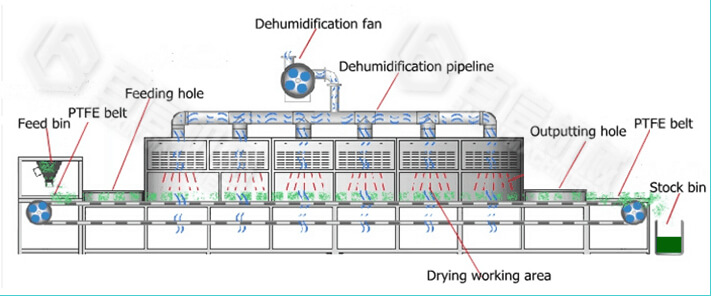

Microwaves are electromagnetic waves at a frequency of 300 MHz to 300 GHz. The material in the heating medium in the molecules of water is a polar molecule. It is the rapidly changing under high-frequency magnetic field, its polarity orientation will be with the change of external electric field changes, resulting in molecular motion and friction between the effect, this field of the microwave field can be transformed into thermal energy within the medium, the temperature of the material increased, heating and puffing a series of physical and chemical processes, to achieve the purpose of microwave heating and drying.

During the equipment is working the microwave generator produces the microwave. The materials enter into the heating chamber by conveyor. At this time, moisture and bacteria inside the material evaporate under the action of microwave energy to achieve unfreeze sterilization ripening fixing drying purpose.

Potato drying process

Place the potato on the conveyor belt of the microwave dryer. The potatoes are dispersed on the conveyor belt through a homogenizing device on the conveyor belt. During the operation of the equipment, the microwave generator generates microwaves. The potato enter the heating chamber through the conveyor belt. At this time, the water and bacteria in the potato evaporate under the action of microwave energy to achieve the purpose of sterilization and drying. The drying time is 5-10 minutes. The dried potatoes are discharged from the discharge port.

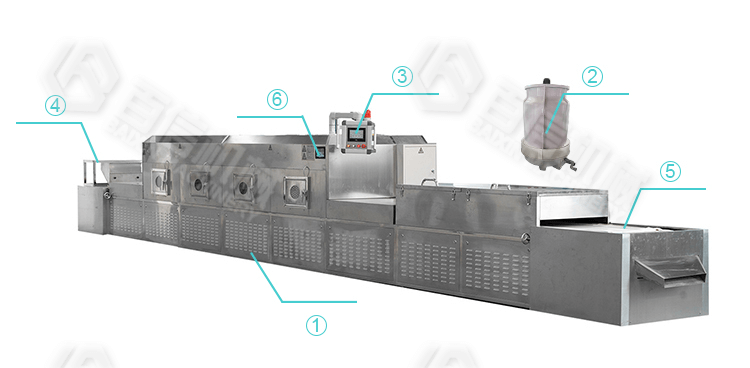

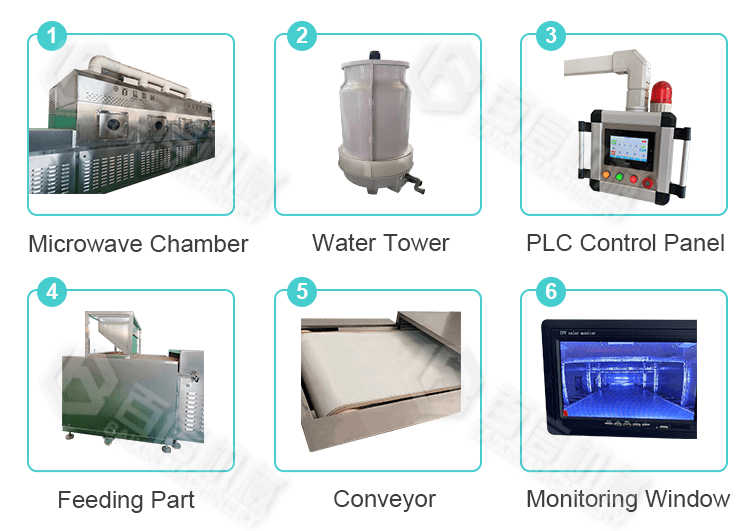

Components of microwave drying machine

Why do customers choose our / Microwave drying machine advantages

1:Fast processing efficiency:

It takes about a few minutes to complete the process from feeding to discharging. The processing efficiency is fast and the effect is good。

2:Uniform drying effect。

The microwave dryer can make all parts of the material have the same effect.

3:Drying and sterilizing simultaneously, tunnel type design, cover small area, continuous production,

4:Clean and sanitary: it will not pollute the material, nor change the color, fragrance, and nutritional content of the material.

Microwave drying machine parameters

| Model | Size(mm) | Power | Dehydration rate | temperature control |

| BX-10 | 6300*665*1800 | 10KW | 10kg/h | 0~400℃ |

| BX-15 | 6300*950*1800 | 15KW | 15kg/h | 0~400℃ |

| BX-30 | 8500*1500*1800 | 30KW | 30kg/h | 0~400℃ |

| BX-50 | 10500*2000*1800 | 50KW | 50kg/h | 0~400℃ |

| BX-60 | 10500*2000*1800 | 60KW | 60kg/h | 0~400℃ |

| BX-80 | 12500*2000*1800 | 80KW | 80kg/h | 0~400℃ |

| BX-100 | 14500*2000*1800 | 100KW | 100kg/h | 0~400℃ |

| BX-120 | 16500*2000*1800 | 120KW | 120kg/h | 0~400℃ |

| BX-150 | 20000*2000*1800 | 150KW | 150kg/h | 0~400℃ |

| BX-160 | 20000*2000*1800 | 160KW | 160kg/h | 0~400℃ |

| BX-180 | 22000*2000*1800 | 180KW | 180kg/h | 0~400℃ |

| BX-200 | 23400*2000*1800 | 200KW | 200kg/h | 0~400℃ |

| Can be customized according to user requirements. | ||||