Cassava Mesh Belt Dryer Machine Delivery To Myanmar

Our Myanmar customers have been in the cassava business for many years and have their own plantations. We learned through the internet that we are engaged in the manufacture of drying equipment and consulted with us on cassava drying. At the same time, the customer consulted many drying manufacturers, and finally chose to make a deal with us, because our equipment is more professional, the output is large, and the degree of customization is high.

The customer requires that the drying output of cassava is 1500kg/h, and the heat source is electricity. We recommend the customer to use a heat pump as the heat source, which is more energy efficient. This set of cassava mesh belt dryer has large output, continuous production and simple installation and operation.

According to the customer's request, we recommended him a 12-meter 4-layer multi-layer mesh belt dryer. The output of this dryer is 1500kg/h, and the drying temperature is 40-100℃. Continuous production, short drying time, simple installation and operation.

| 12m Heat Pump Mesh Belt Dryer Machine | |

| Nation | Myanmar |

| Drying material | Cassava |

| Capacity | 1500kg/h |

| Dehydration ratio | 75% |

| Drying temperature | 40-100℃ |

| Drying time | 0.5-5h |

| Heat source | heat pump |

| Voltage | 380V |

| Power | 153.12kw |

| Warranty period | 1 Year |

| Core advantages | Continuous automatic work/ Large output/ Dryer time short/ Flexible heat source selection |

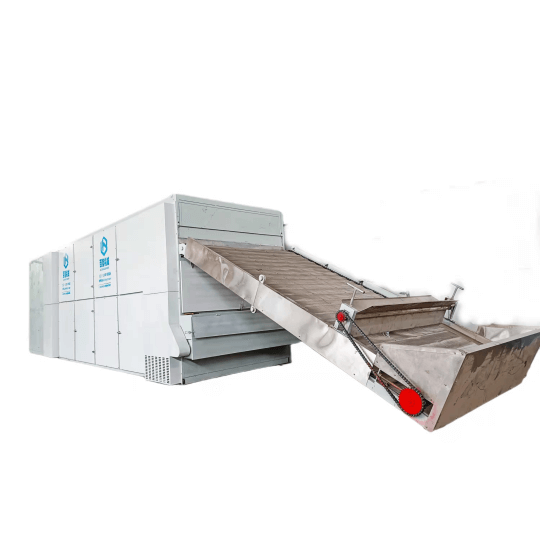

Working principle of mesh belt dryer machine

Cassava mesh belt dryer machine is a kind of continuous production drying equipment. Its main working principle is to spread the cassava evenly in the network. The cassava is moved in the dryer by the operation of the machine, and the hot air draws out the water vapor of the cassava. so as to achieve the purpose of drying.

The operation temperature is 40-80 degree centigrade. And the dry cycle is 1-2 hours.

Cassava drying process

1:Place the cassava on the conveyor belt of the cassava dryer. The cassava is spread on the feeder by the homogenizing device on the conveyor belt.The stacking thickness of cassava is 10-20CM.

2:After the cassava enters the cassava dryer, it runs in an "S" shape in the dryer. The transmission part of the cassava dryer adopts a variable-frequency speed-regulating motor, which can control the internal operation time of the drying according to the difference of the water content of the cassava.

3:The wind speed and wind pressure generated by the hot air blower make the hot air fully and evenly distributed inside the cassava dryer. The hot air naturally moves upward, passing through each layer of the mesh belt, plus the movement and rolling of the cassava, Make the cassava fully contact with the hot air, fully heat exchange, and improve the drying efficiency. The dried cassava will drain through the last layer.

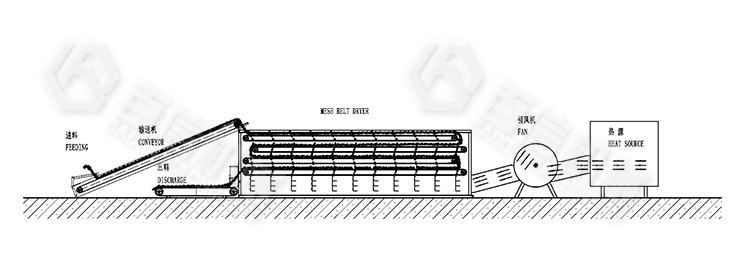

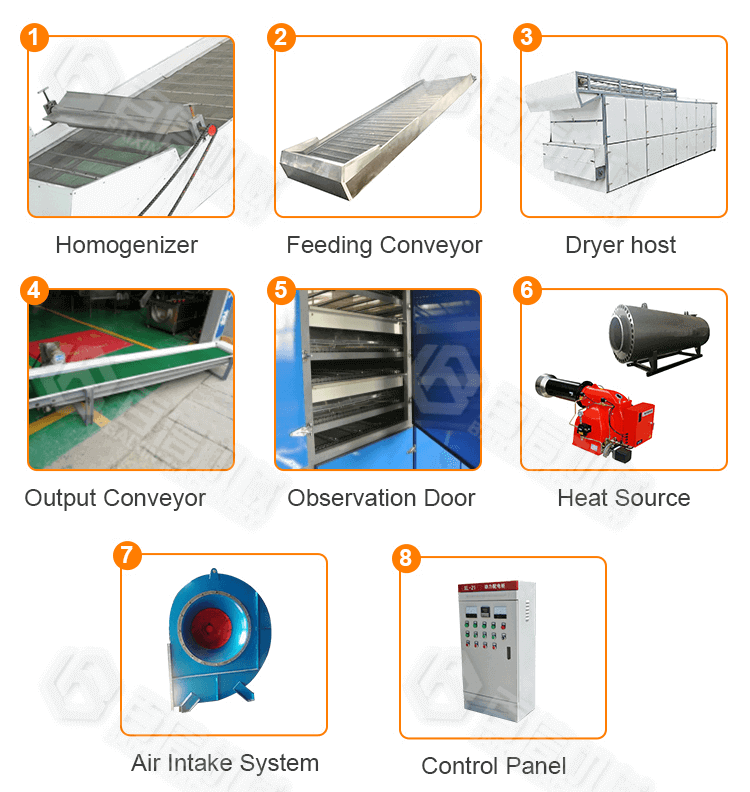

Components of mesh belt dryer machine

Why do customers choose our / Mesh belt dryer machine advantages

1.Middle and low temperature dehumidification drying

The Baixin customized conveyor mesh belt large food dehydrator drying fruits and vegetables in 50℃~80℃, articles does no damage, no moldy and maintain nutrition.

2.Use heat pump technology

The Baixin customized conveyor mesh belt large food dehydrator with high efficiency through the use of a heat pump system for removing air humidity.

3.Working in wholly sealed drying system, hygiene and energy conservation

Drying in a closed sealed system, no foreign material pollution. Efficiency is irrelevant to external environment, that can maintain high energy efficiency at all seasons. No hot air and water vapor loss maximize energy recovery.

4.Running Stable, operating easily

Graphical touch control system, automatic intelligent control and demands no human duty after setting.

5.Without Installation, it can be used by connecting the power supply.

Mesh belt dryer machine parameters

| Continuous mesh belt dryer list | |||||||

| Model | operation temperature | drying time | thickness of the material | the size of motor | capacity | heat source | total power |

| BX-2*6M | 40-120℃ | 0.5-5h | 50-200mm | 6*2*2.5 | 200-400kg/h | electricity | 66.5kw |

| natural gas/propane | 12.22kw | ||||||

| coal/wood chips | 13.72kw | ||||||

| steam | 11.22kw | ||||||

| BX-2*9M | 9*2*2.5 | 500-800kg/h | electricity | 79.76kw | |||

| natural gas/propane | 20.12kw | ||||||

| coal/wood chips | 23.12kw | ||||||

| steam | 16.62kw | ||||||

| BX-2*12M | 12*2*2.5 | 1000-1500kg/h | electricity | 153.12kw | |||

| natural gas/propane | 33.12kw | ||||||

| coal/wood chips | 36.12kw | ||||||

| steam | 25.62kw | ||||||

| Door in Color steel,baffle in Galvanized,the main frame in Carbon steel. | |||||||